Diesel mechanics are often asked to purchase a standard set of tools to use at work each day. While some companies (RDO included) offer assistance programs to help technicians with this, buying tools can get expensive.

Depending on the set, a starting set of mechanic tools can cost $3,000-$15,000 or more. Add in the fact that tools wear out, get lost and sometimes break, and this expense gets even more overwhelming.

It’s not uncommon for a veteran technician to have spent $60,000 or more on tools in their career.

Although it’s always a good idea to set money aside each month and save up for your toolset — that’s what I did when I started — buying diesel tools doesn’t necessarily have to break the bank.

After more than 20 years in this industry, I’ve bought my fair share of tools and developed some methods for saving money on them when I do.

In this article, I’ll list 12 tactics for saving money on your next tool purchase so you can feel more comfortable with the money you spend and walk away with more of it to use elsewhere.

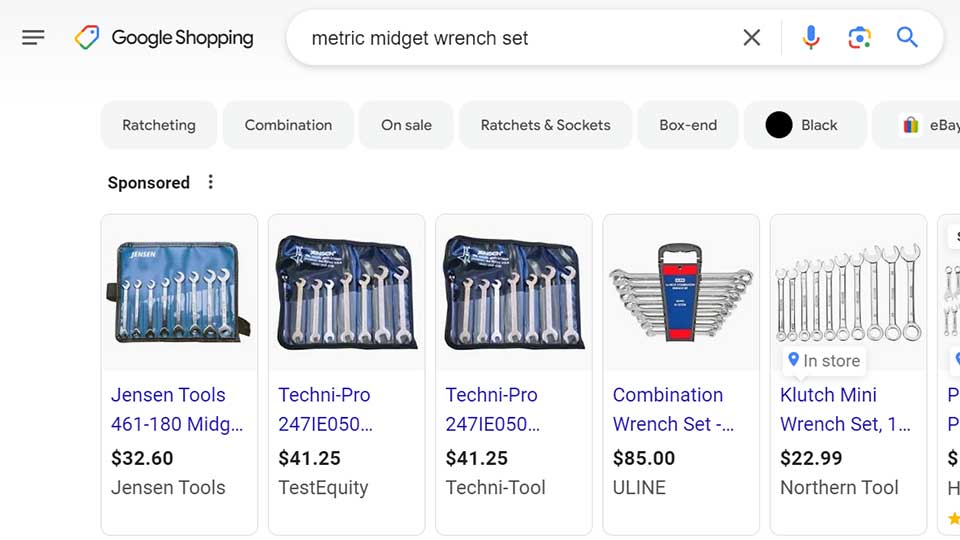

The digital age is here, folks. With it, the internet has brought a lot of buying power to our fingertips as mechanics looking for tools. Now, all you need to do to compare tool prices is search for them on a search engine like Google or Bing. Type in the product you’re looking for, like “metric midget wrench set,” and compare the results along the top.

When you do, you’ll see wrench sets from Home Depot, Snap-On, Lowes, Amazon and other companies. Results will differ in price based on the size and type of the set and the manufacturer. My best advice here is this: You get what you pay for.

However, if you’re looking to save money, this is a good way to start your search — simply filter results based on price.

Another tactic you can use to cut some costs on your next tool purchase is to go to your local pawn shop or second-hand store. Sometimes, diesel technicians who leave the profession decide to sell their tools to one of these businesses. If they have them, you will be able to find some tools at a steep discount from what you’d otherwise pay.

While these will be used tools (sometimes heavily) and you might not be able to find a complete set of anything, it’s a good way to fill in your toolbox for a reasonable price.

You can find some good, lightly used diesel mechanic tools online on platforms like eBay and Facebook Marketplace. Sometimes, you can even find unused tools that people are selling. Search for the tool (or set of tools) you’re looking for and whether you’re looking in a certain area or if you’re willing to pay to have it shipped to you.

These platforms make it easy for people to buy and sell all kinds of things (tools included). So, if what you’re looking for isn’t on there now, it probably will be in the future. Set an alert to get notified (via email or push notifications) if something matching your search comes up in the future.

As a diesel technician working for a particular company for a while, you’ll start to establish relationships with salespeople from tool manufacturing companies like Matco, Snap-On and Cornwell.

When you do, and you have the opportunity to buy tools directly from this person, sometimes discounts are offered. This is particularly the case when you’re looking to make a larger purchase (like a significant portion of your toolset). In these instances, it’s not uncommon to receive a discount from your point of contact, like 10 percent, as a thank you for making the purchase.

While buying your tools in bulk will be a large upfront expense, these discounts can soften the pain of this purchase a little bit. Plus, you’re getting brand-new products that should last longer than used tools.

Financing your tools is also an option. Some manufacturers provide low-interest/no-interest financing to help technicians get tools and pay for them over time. While you want to limit the amount of interest you end up paying, this could be a good option if you need tools now but would prefer to pay for them over time.

There are a few ways an employer may give their technicians tool-purchase assistance.

Reimbursement program: They will reimburse you for a portion of the dollars you spend on tools in a year, often based on the hours you work.

Tool allowance: They will give you a set dollar amount to spend on tools, this often increases based on your years of service with the company.

Tool incentive program: They will help you buy your set of tools up to a certain amount of money, often tied to achievement.

If you work for a company with any of these, take advantage of them. They are just another benefit of working for that business and can significantly cut down the money you spend on tools.

Note: receipts are often required to take advantage of these programs. If you want tool incentives through your employer, make sure you use a tactic where you’ll get a receipt.

Whenever a technician gets a new piece of tooling, they’re faced with a decision: What to do with their old version. Often, tools can pass through the service shop, from one technician to another, at a significant discount.

This recently happened in the RDO shop in Casper, WY, where one technician bought a new toolbox and a newer technician purchased his old one.

Before you stray too far, consider asking around your shop first to see if anyone has some old tools to sell.

Another way to put some money back in your pocket when buying new tools is to trade in your old ones. Some tool manufacturers will accept a used set of tools and give you a kickback through purchase credits.

If you have tools to get rid of and the manufacturer will accept them, trade in your tools to save money on future purchases.

Like other products, tools go on sale. As manufacturers release newer versions or to drum up purchases, you can expect regular sales throughout the year.

Use these as opportunities to save money on the wrenches, sockets, pliers and ratchets you need. If you can wait for a sale to come around and stay up to date with when they’re happening (a good way to do this is to follow the company on social media), you can save money on your tools.

This kind of ties into the previous point, with a slight twist. Yes, social media platforms like Facebook, Instagram and TikTok are great ways to stay in touch with a company’s sales and you should use them for that.

However, YouTube is a good place to get discounts, too.

Find videos of people who review the product(s) you want to buy. When you do, these people often have affiliate links that give you a discount on the product if you buy it through their link. This is beneficial because you get a discount (usually 5-10 percent) while also hearing their opinion on the product itself

Another way to save money on diesel tools is to ask for advice from other technicians. Some people have a good perspective on what’s worth buying and what’s not. Find out what brand they recommend for wrenches, ratchets, toolboxes and socket sets and if they have any advice on what to avoid.

Learning from other people’s experience buying tools can help you get the right stuff and save you money in the long run.

Related Article: 10 Great Diesel Mechanic Tool Companies to Consider in 2025

My final piece of advice is to do your research. The more reviews you read and the more tools you handle, the better off you’ll be. Look up video reviews where tools from different manufacturers are compared, ask your colleagues questions, read reviews online and spend some time looking at tools in person.

Another thing you’ll find as you buy more tools is that there can be some overlap between manufacturers — the same tool, just a different logo. When this is the case (mostly with hand tools), you can get the same tool for a different price. For example, Grey Pneumatic makes a lot of sockets for companies like Matco, but the price changes based on what brand you buy.

Now that you have these 12 tactics for saving money on your next tool purchase, you might also wonder what exactly you need to have a complete set.

Here’s another article I wrote breaking down what’s included in a great set of heavy equipment tools. If you have any questions, please don’t hesitate to reach out to our careers team.

RDO Equipment Co. is hiring service technicians in multiple locations throughout the U.S.

These team members receive quarterly profit-sharing payouts, ongoing training through our in-house capstone program, full benefits, career path leveling and yearly tool reimbursements.

Learn more about our service technician careers and find an opening near you.