Hammett Excavation, a family-owned company with more than 60 years of experience handling any excavation job in Texas and other Southwest states, first embraced machine control and GPS technology for their John Deere excavators more than ten years ago.

“I demoed it for a day,” said General Manager of Construction Equipment Technology, Michael Miller, describing the first time he highlighted how an excavator's productivity vastly improves with machine control technology.

Harry Hammett started the company and eventually passed it on to his son, Gaylon, now the acting CEO. After Miller’s demonstration, Gaylon recalls his father asking if he could keep the GPS technology. He wanted to reinstall John Deere's SmartGrade™ on his excavator to finish the job faster.

"He quickly paid for the new unit and embraced all of its (SmartGrade) benefits," Gaylon said.

Gaylon recalls Harry saying, “Why am I paying for that surveyor when I could be paying for that dozer? I can be much faster in production with the [GPS-equipped] dozer. Let’s start putting it on all our equipment.”

Miller worked with Harry to deliver and install John Deere’s GPS technology, SmartGrade every other month in the following two years., Miller brought technicians to train Hammett team members on their new GPS-equipped excavators. Using GPS-equipped heavy equipment “was the best thing we could ever do,” Gaylon says.

“When my father saw it work, he was all in," he said.

Matt Stromberg, once a service technician and now a GPS technology expert, has worked with Miller and other RDO team members to train Hammett team members. Hence, each operator understands how GPS technology can improve consistency and productivity.

“You can have all the right technology in the world, but team members make the company," Gaylon said. With technology and partnering with RDO, Hammett's team grew with technology to enhance its effectiveness.

Watch Gaylon and the Hammett Excavation team share their story from the job site.

"Even with all the new iron in the world, you won't be productive without the right people," Gaylon said.

Darin Stroud, Vice President of Hammett Excavation, remembers business increasing through the years with technology.

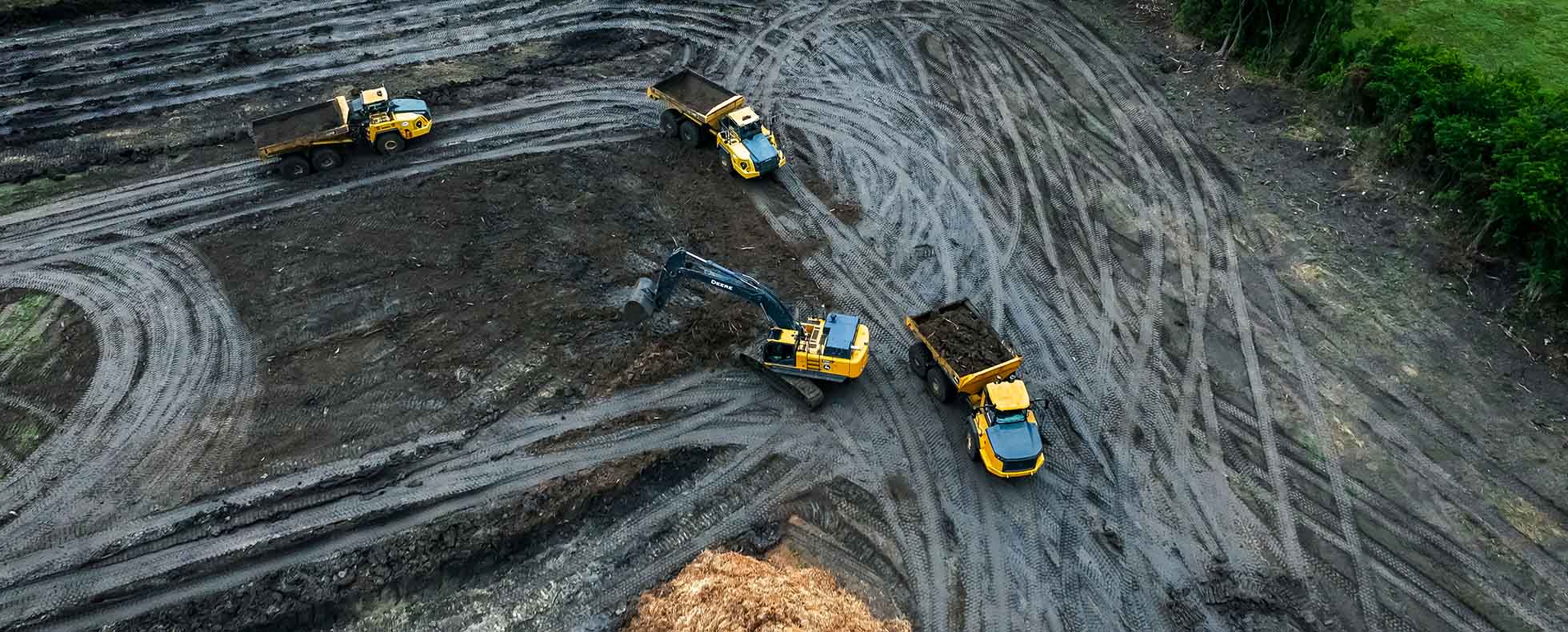

"I've seen the fleet grow from just two 850 excavators to 25 machines all fitted with SmartGrade," Stroud said. In addition to excavators, the Hammett team uses motor graders and skid steers to complete large, complex residential projects. Since Stroud started, Hammett has grown from 30 to more than 300 team members.

"Other companies avoided crossing that line to equip their entire fleet with GPS, oftentimes because of the required financial investment," Gaylon said. "They didn’t even have that chance to see the incremental productivity gains it offers on nearly every job."

By embracing SmartGrade, Gaylon and Stroud could automate grade control for excavators working on specific residential housing pad sites. Hammett's crew completes soil moisture conditioning to build a structurally sound housing pad. Soil moisture conditioning is a process that prepares the soil for building by reducing or increasing soil moisture levels. When levels are too high or too low, it will lead to unstable ground that can damage a home’s foundation. Too much moisture can cause swelling, problems with over-compaction, and unsuitable bearing capacity. When moisture levels are too low, sediments can shrink, creating voids in the soil and leading to foundation failure.

So, before the work starts on a job site, Stroud works with a geo-technician who performs soil tests so that Stroud can define the exact amount of compaction needed based on moisture and other environmental factors. Through these tests, the geo-technician and Stroud will determine the amount of soil conditioning and site grading required to achieve the exact compaction for the job. Then, they bring this plan to the developer with Hammett’s QA/QC Framework, a simple document Stroud prepares to explain what his team will do to ensure quality and efficiency despite any other challenge.

Once this is completed, it’s time for Hammett’s equipment technology to shine. Stroud sets a predetermined depth for his team to dig based on the approved compaction. Then he checks compaction in real-time throughout each residential job by monitoring Hammett’s fleet, including John Deere 850 Dozers, excavators and articulated dump trucks. He does this with GPS technology.

Stroud says integrating Hammett’s equipment fleet with GPS leveled up their ability to complete projects on schedule accurately. Conservatively, he says Hammett’s efficiency has increased by 70%. In recent years, Hammett’s increased productivity has kept their team competitive and profitable despite economic or labor challenges.

“I don't think there's any way that we would be this big and be able to manage the work and the business without this technology,” Stroud said. “Our in-house staff does everything from start to finish for residential site development projects.”

Gaylon and Stroud agree. Their willingness to make the leap into the world of construction technology, with help from a committed and knowledgeable technology provider like RDO, is their recipe for success.